Those familiar with detention and correctional environments know that the difference between a shut, secured door and an open door can mean the difference between business as usual and disaster. A food pass or shackle lock that has been tampered with opens the door to residents passing contraband and communications. A malfunctioning cell door lock is a security risk not only for a facility’s residents but also for its staff. That is why, when it comes to securing your facility, it is crucial to remember that not all locks are created equal.

But how do you choose the right cell locks for your high-security facility?

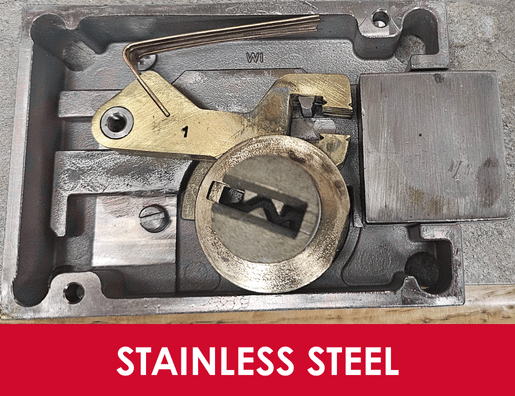

When detention equipment contractors, sheriffs, wardens, correctional officers, architects and engineers took a step back and asked this question, Willoughby was quick to step forward and give the answer – Stainless Steel Cell Locks. Improving on industry-standard designs by implementing customer feedback and using stainless steel for increased tensile strength and corrosion resistance, Willoughby Locking Systems designs its products to stand up to even the most brutal environments.

This blog is here to help you understand why Willoughby chose to use stainless steel instead of the industry standard mild steel. We will also explore whether using stainless steel will be the right choice for your facility.

How Stainless Steel Cell Locks Can Enhance Facility Security

What is the point of a lock? To keep something or someone in or out of an area. Usually, in the detention world, this means keeping someone in their cell, cell pod, day room or keeping them out of restricted areas such as an armory, supply closets, administrative areas, or the greater outside world.

Imagine an inmate who only has time on their hands attempts to leave or gain access to a restricted area, what options do they have?

Breaking through the door is next to impossible in modern detention settings that utilize reinforced hollow metal doors.

Break the hinges? Again, it is highly unlikely as these hinges are stainless steel. So, what is their best approach?

That leaves the most popular option—targeting the lock. Despite common perception, picking a cylinder is not the biggest threat to a lock’s security. Instead, the biggest threat is gaining access to and manipulating or jamming the lock’s internal systems. From our experience, this is commonly done with access through the latch/bolt hole(s) when the door is open.

(As a rule of thumb, a closed door is the best protection for a detention lock.)

With high-quality stainless steel cell locks, you can minimize these risks.

Stainless Steel Vs. Mild Steel: Which Lock is Better for Security?

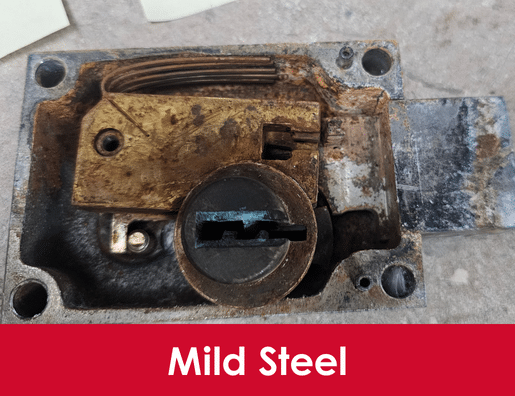

When comparing mild steel to stainless steel cell locks, it becomes clear that stainless steel’s superior strength and lower tolerances reduce vulnerability in detention locking systems. The comparative softness of mild steel continues to play a factor in potential lock failure due to the wear of materials with regular use and abuse.

Another point of failure of a mild steel cell lock, outside of external factors such as toothpicks and playing cards, is corrosion. Mild-grade steel has less resistance to corrosion, making it more prone to rust. Corrosion is a complex degenerative process that worsens with time, leaving abrasive debris perpetually increasing wear.

Processes such as heat processing, electroplating, and galvanization can improve the properties of mild steel to make it more comparable to high-grade stainless steel. However, these processes are short-term solutions that are longer and dirtier to produce, to the point that dust from mild steel production can even induce corrosion on stainless steel.

When using stainless steel, locks can maintain the same high tolerances they left the factory with for longer. This means that inmates are less likely to inhibit the function of the locks due to the materials being harder and, therefore, experience less wear, keeping operation smooth. Due to the corrosion resistance of stainless steel, internal parts are less likely to fail due to compounding wear.

Willoughby Locking Systems: The Sole Manufacturer of Stainless Steel Cell Locks

Willoughby Locking Systems uses 100% stainless steel to construct our locks. Our lock cases, mountings, castings, and fasteners are made of stainless steel to not only protect from corrosion but also ensure Willoughby locks will wear less and operate at the highest level for years to come. Willoughby produces all of its products in a clean shop free of mild-grade steels, guaranteeing processes associated with mild-grade steel have not contaminated our stainless steel products.

Investing in Willoughby’s Stainless Steel Cell Locks ensures unparalleled security, durability, and peace of mind for high-security facilities. Engineered to withstand the use and abuse of the detention and corrections industry, when you choose Willoughby for your facility, you can rest assured your facility is protected to the highest standards.